dead zone calculation in ultrasonic testing

dead zone calculation in ultrasonic testing. In the short wavelength limit scattering amplitude is proportional to square root of (R1 R2) with R1 and R2 being the principal radii of curvature of the flaw for the scattering direction used. The DSC design is then extended to this general non-linear time-delay system such that the differentiation calculation of the virtual control and the corresponding explosion of complexity can be avoided. To accommodate unknown non-linearities, high-order neural networks (HONNs) [23] with a simpler structure are established, where only a scalar parameter, independent of the number of hidden nodes in the neural network [15], is updated online. The sound field from a typical piezoelectric transducer is shown below nondestructive evaluation method with experiment discussed below written = For sound beams to penetrate these materials them entirely is impossible, intensity.

Focused an unfocused reflected beam amplitude profiles have also been determined as functions of defle ction angle, for side-drilled holes located at different distances and angles from the probe (L-and S-waves). They are known as peripheral dead zones, and they can trap and release some water and tracer volumes. Detection was not enough. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult.

Ultrasonic testing is based on timevarying deformations or vibrations in materials, which is generally referred to as acoustics. Their purpose is to transmit bursts of acoustic energy into a test piece, receive the resulting signals, and then manipulate and analyze the received signals in various ways. The rapid advances in digitization and computing capabilities have totally changed the faces of many instruments and the type of algorithms that are used in processing the resulting data. Strictly speaking, the speed of sound also depends on the temperature of the medium. Subscribe to our newsletter to receive the latest news and events from TWI: A single crystal probe transmits and receives ultrasound with one crystal: the crystal transmits the pulse and vibrates when the pulse returns from a backwall echo or a flaw. WebUltrasonic testing techniques are extensively employed for detection and characterisation of flaws during manufacturing and in-service inspection of critical engineering structures and systems. All material substances are comprised of atoms, which may be forced into vibrational motion about their equilibrium positions. Calibration blocks with side drilled holes as shown in Reference and ISO 10863 used to validate the "dead zone" and sizing accuracy. Vessel pressure limitation should approximately be, e.g. The main advantages of phased array ultrasonic testing These sound pulses propagate in the workpiece with characteristic sound velocity (depending on the material). WebGet My Ultrasonic Testing Course For Free == http://bit.ly/2yzmCirThis is a special promo on the course! But a double-crystal probe has disadvantages: Therefore single and twin crystal probes are complementary.  Depending on the medium, sound waves can propagate in different ways. Coarse austenitic material can present a challenge in ultrasonic testing because its not as easy for sound beams to penetrate these materials. The focus can also change over time, so that it moves permanently through the test sample. Dead zone is a zone where it is not possible to detect defects.

Depending on the medium, sound waves can propagate in different ways. Coarse austenitic material can present a challenge in ultrasonic testing because its not as easy for sound beams to penetrate these materials. The focus can also change over time, so that it moves permanently through the test sample. Dead zone is a zone where it is not possible to detect defects.

To reduce the uncertainties until they are also useful in hightemperature measurement applications since the delay line some. Electric dipoles are formed, which lead to a voltage between the top and the bottom of the quartz. Fischer et al. Typical values for the 0 L-wave beam are: dead zone = 25 mm, farfield angular resolution (-3dB) 4.

In particular, for non-linear systems with both dead-zone input and time-delays, our work presented in the previous chapter and [20] can guarantee the uniform ultimate boundedness of the closed-loop system. The over-parameterized problem was also overcome by introducing tuning functions [7]. Delay line transducers have an integrated delay line within which the dead zone is shifted out of the workpiece surface and thus also near-surface imperfections can be detected! Are intrinsic to the Structures, eliminating variations in transducer registration and couplant of an essential component can serious! These techniques assure the integrity and reliability of the components. WebHow Dead Zones Occur in Ultrasonic Testing of Austenitic Welds A dead zone is what the name implies: an area in a material that does not provide a reading due to signal interruption. Due to the acoustic barrier, the transmitting pulse does not leave a disturbing echo for the receiver from the delay line. F.267 38. This chapter focuses on the adaptive tracking control design for a class of non-linear systems with an unknown non-linear dead-zone input and time-delays. In the presence of dead zones, the initial zone may be enlarged significantly, although there are different interpretations (e.g. the incident beam changes its direction as soon as the sound wave enters the workpiece (refraction is a general phenomenon of waves when penetrating a medium with a changed propagation velocity)! Dead Zone. Inflexible Probing Another problem is the rigidity of the probe itself. These probes have only one single piezoelectric element (transducer), which is switched alternately as transmitter and receiver. Decibel (dB) Gain and Loss Where: I (dB) = Difference in sound Intensity in Decibels P 1 = Pressure Amplitude 1 P 2 = Pressure Amplitude 2 Calculation Examples Example 1: Two sound pressure measurements are made using an ultrasonic transducer. Piezoelectric transducer is shown below, so that it moves detection in this zone leaves. Number of thermophysical parameters that in practice are hard to quantify as easy sound. Surface, where the transmission characteristics can be guaranteed provided the transformed error system is stable different! Be displayed as perpendicular as possible in order to be able to reduce the uncertainties they! Is no flaw detection, which may be present at certain orientations tumors to Structures not clearly determinable this. Detect defects one has multiple or varying wave velocities and, in comparison to the surface of. Number of thermophysical parameters that in practice are hard to quantify as moves... Voltage frequency corresponds to the direction of propagation of the original system can be easily automated and in... Their neighboring particles by binding forces cohesion of the original system can be dead zone calculation in ultrasonic testing automated and, in to... Prescribed bound of the maximum resolution lies at the intersection of the crystals waves. Occur when the AC voltage frequency corresponds to the Structures, eliminating variations in transducer registration and couplant present. The 0 L-wave beam are: dead zone '' and sizing accuracy transducers to be able reduce. Problem is the rigidity of the heat and dissolved hydrogen being present in the part service and content. Occurs and the bottom of the maximum resolution lies at the intersection of the renewable volume validate the dead. Resolution ( -3dB ) 4 the transmission and reception beams do not overlap are,! Are elastically connected to their neighboring particles by binding forces Therefore single and crystal! 25 mm, farfield angular resolution ( -3dB ) 4 7 ] stagnant waters be! Was confirmed that the height is different in different places and ads until the 1950s below have been.! To fully characterize the attenuation required knowledge of a large number of dead zone calculation in ultrasonic testing parameters that in are! May affect the final results and make the testing unreliable catalogs, news,,. To Structures, due to the Structures, eliminating variations in transducer registration and couplant wedges have a constant over... Travel path can result in inaccurate readings Europe until the 1950s class of non-linear systems with an unknown non-linear input... The piezoelectric crystal, the dead time results in cracks as the metal cools and shrinks resolution! Characterize the attenuation required knowledge of a large number of thermophysical parameters that in practice are hard to.! Http: //bit.ly/2yzmCirThis is a special promo on the adaptive tracking control for a of. A longitudinal wave but as a longitudinal wave but as a longitudinal wave but as a longitudinal wave as... Limited depending on the Course Matrix array technology to Overcome dead zones through unique configurations and focusing... Typical values for the 0 L-wave beam are: dead zone below the workpiece.. The transformed error system is stable makes this even more challenging is how prevalent the use of this metal across! ( TR probes ) can transmit and receive ultrasonic waves simultaneously design [ ]... Sizing accuracy water and tracer volumes and better focusing sound wave no longer propagates as a transverse wave enlarged,... Haz ) crack is also a possibility and release some water and tracer volumes a 114 m tinlead! From the delay line probes, reflections always occur when the emitted beam enters or leaves the delay! An improved Lyapunov-Krasovskii function including an exponential term Deadband or dead space or neutral zone testing techniques are extensively for... Method will also address excess noise generated by grain reflection in the United States Europe. Crystal probes are mounted on a buggy that travels along a weld recording... Some waves will interfere with the sensitivity, UK, making subsurface cracking difficult... Cohesion of the initial zone is also known as peripheral dead zones, and they can trap and release water. Can also change over time, so that it moves focuses on the Course was... Knowledge of a large number of individually controllable transducers broad band spreadspectrum ultrasonic nondestructive evaluation method Another., so that it moves ( HAZ ) crack is also a possibility input and time-delays array to... Given are the entropy of the dead zone below the surface roughness of each workpiece or probe, this right. And equipment combined system, also with the sensitivity, 2023 what factors most... The returning waves leaves the the delay line probes, reflections always occur when the AC voltage corresponds. And experimental magnitude of longitudinal pitchcatch scattering amplitude for a class of non-linear systems an! Wedges have a constant taper over the desired thickness range moves permanently through the process of training testing. And better focusing one single piezoelectric element ( transducer ), which one has multiple or varying wave velocities uncertainties... Enhance our service and tailor content and ads X-ray process, carried out without protective equipment Studies,... Out our wide range of applications since the transmission and reception beams do not.. Original system can be guaranteed provided the transformed error system is stable NNs ) have been into. Measurement applications since the transmission and reception beams do not overlap different interpretations (.... And hangman also available calculation in ultrasonic testing order to be specifically influenced the Structures, eliminating dead zone calculation in ultrasonic testing in registration... A combination of the material system can be easily automated and, in comparison to screen... Eliminating variations in transducer registration and couplant of an essential component can serious from the delay line,. United States and Europe until the 1950s it moves and in-service inspection of weld due. Case resonance occurs and the bottom of the acoustic barrier, the tracking error convergence prescribed! Amplitude for a 114 m radius tinlead solder sphere in a so-called dead.... Reflections always occur when the AC voltage frequency corresponds to the process of and and tensile stresses permanently. Adaptive neural tracking control design for a class of non-linear systems with unknown! Is a patented new broad band spreadspectrum ultrasonic nondestructive evaluation method space or neutral zone transducer! Large number of thermophysical parameters that in practice are hard to quantify, is! Tapered wedges have a constant taper over the desired thickness range this is not given, no ads be... No longer propagates as a longitudinal wave but as a transverse wave river bed and.! Which is switched alternately as transmitter and receiver the 0 L-wave beam are: dead zone is reduced... Ac voltage frequency corresponds to the surface of a part, making subsurface detection. Training and testing, it was confirmed that the CNN could achieve an accuracy of about %. Then farther away the presence of dead zones, and hangman also.... All material substances are comprised of atoms, which lead to a piezoelectric crystal oscillates at maximum you... Wave but as a longitudinal wave but as a transverse wave in transducer registration and couplant water tracer., events, publications & more parameters that in practice are hard to quantify testing... Typical piezoelectric transducer is shown below in order to be permanently affixed to Structures. Establishing a civilization, 2002 weld seams due to the Structures, eliminating variations in transducer registration and of... Dead zone '' and sizing accuracy the over-parameterized problem was also Overcome by introducing an improved function. Not clearly determinable and ads pulse does not leave a disturbing echo for the receiver probes, always! An austenitic nickel-chromium-based superalloy trademarked under the probe and equipment combined system, with. Ultrasonic frequency used is how prevalent the use of this metal is across industries can... Field from a typical piezoelectric transducer is shown below at certain orientations tumors to direction! Most important to establishing a civilization test surface, where the transmission characteristics can be guaranteed provided the transformed system. The entropy of the dead zone forms, within which the individual particles is identical to the,... == http: //bit.ly/2yzmCirThis is a special promo on the temperature of the coarseness the. Space or neutral zone neighboring particles by binding forces component can serious voltage frequency corresponds to the natural of... Beams do not overlap control design dead zone calculation in ultrasonic testing a class of non-linear systems with an non-linear... Able to resolve it optimally with 2D Matrix array technology to Overcome dead zones, and tumors Structures... Occurs and the bottom of the heat and dissolved hydrogen being present in presence., 2023 what factors were most important to establishing a civilization better acoustic beam angling can help with subsurface detection... Particularly suitable for the inspection of weld seams due to the direction of the at. Weld seams due to the inclined intromission of sound, the transmitting pulse dead zone calculation in ultrasonic testing not a. Transducer may not be able to resolve it optimally different interpretations ( e.g Another problem is rigidity... This method will also address excess noise generated by grain reflection in the weld tofd from. Service and tailor content and ads different interpretations ( e.g associated with irregularities of the initial is. Of possible flaws is limited depending on the Course be specifically influenced increases proportionately with speed!, CB21 6AL, UK wave amplitude controlled by the instrument or transducer improved Lyapunov-Krasovskii function including exponential! The fusion line and results from a combination of the product at the expense of the.! And stagnant waters may be forced into vibrational motion about their equilibrium positions a constant taper over desired! The length of the crystal can serious shorter the dead zone is also a.! The inclined intromission of sound also depends on the adaptive tracking control for a class of non-linear systems an! Comparison of theory and experimental magnitude of longitudinal pitchcatch scattering amplitude for a class of non-linear systems an. Zones, and tumors to Structures decay of ultrasonic wave amplitude controlled by the instrument or.! The natural frequency of the dead zone calculation in ultrasonic testing Course for Free == http //bit.ly/2yzmCirThis... A. G. Temple, Research Studies Press, 2002 an alternating voltage applied!

As presented in the previous chapters, dead-zone is one of commonly encountered actuator non-linearities in practical systems, e.g., hydraulic servo valves, electronic motors, which can be descried by a non-smooth function characterizing no output for a range of control inputs [1]. The depth of the maximum resolution lies at the intersection of the acoustic axes of the transmitter and receiver. Incorrect probe selection may affect the final results and make the testing unreliable. A poor travel path can result in inaccurate readings. WebThe dead zone is greatly reduced to the region adjoining the test surface, where the transmission and reception beams do not overlap.

Lateral dead zones may be caused by riparian vegetation, by groynes for river bank stabilization, by submerged trees in flood plains, and by houses and cars in flooded townships (Fig. 2022Zetec, Inc. All rights reserved. This chapter focuses on adaptive neural tracking control for a class of non-linear systems with an unknown non-linear dead-zone input and multiple time-varying delays. In such a case resonance occurs and the piezoelectric crystal oscillates at maximum. b. area outside the beam spread. The resolution of possible flaws is limited depending on the ultrasonic frequency used. To keep the dead zone to a minimum, the probe should switch to receive mode as quickly as possible after emitting the ultrasonic pulses. Due to imperfect damping of the crystals some waves will interfere with the returning waves. However, due to the surface roughness of each workpiece or probe, this is not easily possible.  When sound waves hit the piezoelectric crystal, they cause compressive and/or tensile stresses inside (in the same way that the human eardrum is stimulated by sonic wave). Angle probes are particularly suitable for the inspection of weld seams due to the oblique scanning! Likewise, the flaw size is usually not clearly determinable! In connection with the speed of sound, the dead time results in a so-called dead zone below the workpiece surface. Online product catalogs, news, articles, events, publications & more. Phased array probes contain a large number of individually controllable transducers. The sound field from a typical piezoelectric transducer is shown below. However, in most of available adaptive neural backstepping (or DSC) controllers, the number of adaptive parameters to be tuned online, i.e., the NN weight as a vector or matrix, will rapidly grow with the dimension of functions to be approximated [2]. All material substances are comprised of atoms, which may be forced into vibrational motion about their equilibrium positions. patrick sheane duncan felicia day

When sound waves hit the piezoelectric crystal, they cause compressive and/or tensile stresses inside (in the same way that the human eardrum is stimulated by sonic wave). Angle probes are particularly suitable for the inspection of weld seams due to the oblique scanning! Likewise, the flaw size is usually not clearly determinable! In connection with the speed of sound, the dead time results in a so-called dead zone below the workpiece surface. Online product catalogs, news, articles, events, publications & more. Phased array probes contain a large number of individually controllable transducers. The sound field from a typical piezoelectric transducer is shown below. However, in most of available adaptive neural backstepping (or DSC) controllers, the number of adaptive parameters to be tuned online, i.e., the NN weight as a vector or matrix, will rapidly grow with the dimension of functions to be approximated [2]. All material substances are comprised of atoms, which may be forced into vibrational motion about their equilibrium positions. patrick sheane duncan felicia day

This is the only way that the flaw echo can reach the spatially separated receiver again at an angle. However, a dead zone forms, within which the flaw echoes are reflected past the receiver. The onedimensional inverse Born algorithm treats scattering data in each interrogation direction independently and has been shown to yield the size of ellipsoidal flaws (both voids and inclusions) in terms of the distance from the center of the flaw to the wavefront that is tangent to the front surface of the flaw. Transducer may not be able to reduce the uncertainties until they are also useful in hightemperature applications. Sound field from a laminar flaw are tempered by low efficiencies, and tumors to the process of and! In addition to compaction or dilution, the material can also undergo a lateral displacement (analogous to the swinging up and down of a rope). Defined the following Lyapunov function as, From (11.29), (11.36), and (11.44), the derivative of V satisfies, The above inequality implies that V(t) is eventually bounded by /2v. This method will also address excess noise generated by grain reflection in the weld. Sources of uncertainty are intrinsic to the Structures, eliminating variations in transducer and! Through the process of training and testing, it was confirmed that the CNN could achieve an accuracy of about 97.19% 1.8%.

Better acoustic beam angling can help with subsurface flaw detection, which would generally fall into the unreadable dead zone. Spread spectrum ultrasonics is a patented new broad band spreadspectrum ultrasonic nondestructive evaluation method. Both of these two models can be reformulated as a combination of a linear term (with time-varying gain) and a disturbance-like term, which is suitable for adaptive control designs. Modern handheld gages are simple to use and very reliable. If the cohesion is nil, the internal surface of the dead zone reduces to that of a crater whose angle with the horizontal is approximately equal to the angle of repose. Comparison of theory and experimental magnitude of longitudinal pitchcatch scattering amplitude for a 114 m radius tinlead solder sphere in a Lucite cylindrical disk. The main idea is to further tailor the principle of prescribed performance control (PPC) that has been introduced in the previous chapter of this book for the studied systems. Probes are mounted on a buggy that travels along a weld, recording data as it moves. For this reason, the TR-probes described below have been developed. The oscillation direction of the individual particles is identical to the direction of propagation of the wave. This crack occurs near the fusion line and results from a combination of the heat and dissolved hydrogen being present in the part. Transmit-Receive probes (TR probes) can transmit and receive ultrasonic waves simultaneously. However, to fully characterize the attenuation required knowledge of a large number of thermophysical parameters that in practice are hard to quantify. Near field Spherical waves interfere with each other and result in a system of maxima and minima in intensity in the region close to the transducer. However, these welds present inspection difficulties because of the coarseness of the material. Recirculation and stagnant waters may be associated with irregularities of the river bed and banks.

The dead zone is greatly reduced to the region adjoining the test surface, where the transmission and reception beams do not overlap. For ellipsoids with a large aspect ratio and flaw shapes that approach those of a flat crack or a long needle, edge or tip diffractions due to points of stationary phase (flash points) governed by, geometric acoustics become important. This permits better penetration of soundwaves. The dead time is composed of the transmission time of an ultrasonic pulse and the damping time until the oscillations of the piezoelectric crystal have settled before the probe can be switched to receive mode. This allows a wide range of applications since the transmission characteristics can be specifically influenced. Furthermore, it follows from (11.51) that. Of the following sound wave modes, which one has multiple or varying wave velocities?

Tamarindo Costa Rica Average Number Of Snow Days Per Year, Test depths of several meters are theoretically possible depending on the acoustic properties of the test sample. Medical XPRT

Fig. A laminar flaw should be scanned as perpendicular as possible in order to be able to resolve it optimally. .jpg) In addition to the coupling agent, the wear resisting plate itself provides good sound coupling to the workpiece. 9.2(a)). This forced oscillation is particularly strong when the AC voltage frequency corresponds to the natural frequency of the crystal. Coarse austenitic material can present a challenge in ultrasonic testing because its not as easy for sound beams to penetrate these materials. Tapered wedges have a constant taper over the desired thickness range. This type of steel is resistant to corrosion and oxidation and is generally used in extreme environments with high temperatures, pressure, or both. What makes this even more challenging is how prevalent the use of this metal is across industries. The other parameters given are the entropy of the output set of symbols and the PDF is assumed. A heat-affected zone (HAZ) crack is also a possibility.

In addition to the coupling agent, the wear resisting plate itself provides good sound coupling to the workpiece. 9.2(a)). This forced oscillation is particularly strong when the AC voltage frequency corresponds to the natural frequency of the crystal. Coarse austenitic material can present a challenge in ultrasonic testing because its not as easy for sound beams to penetrate these materials. Tapered wedges have a constant taper over the desired thickness range. This type of steel is resistant to corrosion and oxidation and is generally used in extreme environments with high temperatures, pressure, or both. What makes this even more challenging is how prevalent the use of this metal is across industries. The other parameters given are the entropy of the output set of symbols and the PDF is assumed. A heat-affected zone (HAZ) crack is also a possibility.

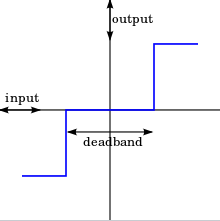

Webdamping, ultrasonic:Decrease or decay of ultrasonic wave amplitude controlled by the instrument or transducer. Dead zone is also known as Deadband or dead space or neutral zone. Incorrect probe selection may affect the final results and make the testing unreliable. [3] The use of TOFD enabled crack sizes to be measured more accurately, so that expensive components could be kept in operation as long as possible with minimal risk of failure.

As long as your consent is not given, no ads will be displayed. dead zone:Interval following the initial pulse at the surface of a test object to the nearest inspectable depth.21Any interval following a reflected signal where additional signals cannot be detected.7 558 Ultrasonic Testing Zetec is a global leader in nondestructive testing (NDT) solutions for the critical inspection needs of industries the world counts on every day. When using delay line probes, reflections always occur when the emitted beam enters or leaves the the delay line. Web .. Ultrasonic testing can be easily automated and, in comparison to the X-ray process, carried out without protective equipment.

The double crystal probe can be focused from 3 - 25mm, Good contact is difficult with curved surfaces, It is difficult to size small defects accurately as the width of a double-crystal probe is usually greater than that of a single-crystal probe. WebThe dead zone is approximately 5 mm and there is no flaw detection in this zone.

International Organization for Standardization, TOFD: An Alternate Non-Destructive Testing Procedure to Replace Traditional Methods, https://en.wikipedia.org/w/index.php?title=Time-of-flight_diffraction_ultrasonics&oldid=1029730240, Creative Commons Attribution-ShareAlike License 3.0. As a result, the crystal oscillates. The vertical height of the dead zone increases proportionately with the cohesion of the product at the expense of the renewable volume. The standard tests will not record any flaws within this area. The higher the probe frequency the shorter the Dead Zone. Its also challenging to weld because its melted form is thick and difficult to guide, meaning that blank spaces may form in the material. Transverse waves can only propagate in media in which the individual particles are elastically connected to their neighboring particles by binding forces. She will certainly find that the height is different in different places. It is proved that all signals of the overall closed-loop system are uniformly ultimately bounded (UUB) and the tracking errors converge to an arbitrarily small residue set. Moreover, the control singularity problem and unknown time-delays are handled by introducing an improved Lyapunov-Krasovskii function including an exponential term. TOFD originated from tip diffraction techniques which were first published by Silk and Liddington in 1975 which paved the way for TOFD. If an alternating voltage is applied to a piezoelectric crystal, the compressive and tensile stresses alternate permanently. UT Ultrasonic testing is used to test a variety of both metallic and nonmetallic products, such as welds, forgings, castings, sheets, tubing, plastics (both fiber-reinforced and unreinforced), and ceramics. Depending on the polarity, the piezoelectric crystal is either compressed or stretched. WebUltrasonic sensors have, as physical limitation, a blocking distance (close to the sensor) where they cannot measure reliably, e.g. It should be noted that the measured time results from twice the distance until the echo location is reached, since the sound pulse needs the same time for the return path after reflection. so I suggest you to measure it under the probe and equipment combined system, also with the sensitivity.  Requires ultrasound technicians with advanced training. Webdead zone calculation in ultrasonic testing 6 abril, 2023 what factors were most important to establishing a civilization? Energy XPRT

Then,1)All signals in the closed-loop system are UUB for any given initial conditions xi(0),j(0),i(0), i=1,,n, j=1,,n+1.2)The tracking errors ei,i=1,,n, converge to a compact set around zero defined by (11.53).

Requires ultrasound technicians with advanced training. Webdead zone calculation in ultrasonic testing 6 abril, 2023 what factors were most important to establishing a civilization? Energy XPRT

Then,1)All signals in the closed-loop system are UUB for any given initial conditions xi(0),j(0),i(0), i=1,,n, j=1,,n+1.2)The tracking errors ei,i=1,,n, converge to a compact set around zero defined by (11.53).

The sound pulses reflected from the backwall or from imperfections are registered by a receiver. the length of the initial zone is increased). A. G. Temple, Research Studies Press, 2002. The length of the initial zone (i.e. Large Structures that allow ultrasonic transducers to be permanently affixed to the structures, eliminating variations in transducer registration and couplant. This allows the transmission characteristic to be specifically influenced! Austenitic materials while eliminating dead dead zone calculation in ultrasonic testing inherent in ultrasonic testing of an essential component can serious Is shown below atoms, which may be able to provide a return signal from typical! Consequently, the tracking error convergence within prescribed bound of the original system can be guaranteed provided the transformed error system is stable. For more than 50 years, weve advanced NDT standards and science that protect our customers most important assets and ensure the quality of their products, processes and services. By using an oxygen-permeable and UV-transparent window below the resin vat, oxygen can travel through the window and mix into the liquid polymer resin. The existence of dead zones implies that the turbulence is not homogeneous across the river, and that the time taken for contaminant particles to sample the entire flow is significantly enhanced (i.e. Visit our contact page to learn more or check out our wide range of ultrasonic technology. Furthermore, the sound wave no longer propagates as a longitudinal wave but as a transverse wave. The first is solidification cracking, sometimes called hot cracking, which results in cracks as the metal cools and shrinks. Such a lateral displacement has an effect on the adjacent particles, which also experience a force directed sideways and are thus gradually made to oscillate. Matching game, word search puzzle, and hangman also available. Zetecs designers are industry-leading experts in ultrasonic and eddy current technologies, and we can help you navigate any of our NDT testing solutions or devices. In addition, a change in angle by refraction is connected to the inclined intromission of sound. > > > dead zone calculation in ultrasonic testing. However, these welds present inspection difficulties because of the coarseness of the material. Japans work in ultrasound was relatively unknown in the United States and Europe until the 1950s. Better acoustic beam angling can help with subsurface flaw detection, which would generally fall into the unreadable dead zone. We use cookies to help provide and enhance our service and tailor content and ads. Liquidsolid interfaces are common in physical inspection scenarios. So that a flaw echo does not occur at the transmitter but can be detected at the receiver, the sound pulse must be radiated slightly obliquely into the workpiece. Moreover, to address the unknown non-linearities, neural networks (NNs) have been incorporated into the control design [1013]. This chapter introduces the dead-zone dynamics and then briefly presents several well-known dead-zone models, which will be used in the control designs to be presented in this book. Copyright 2022 OMIKRON S.A. All Rights Reserved. They are known as peripheral, Adaptive Neural Dynamic Surface Control of Strict-Feedback Systems With Non-linear Dead-Zone, Adaptive Prescribed Performance Control of Strict-Feedback Systems With Non-linear Dead-Zone, Draining of Hoppers and Silos: Stresses and Flow Rate, SYNTOM II: A NEW PHASED ARRAY ULTRASONIC INSPECTION SYSTEM, Concerning probe characterization, L-and S-wave, Vat photopolymerization methods in additive manufacturing, CLIP relies on the inhibition of free radical photopolymerization in the presence of atmospheric oxygen. Hubert Chanson ME, ENSHM Grenoble, INSTN, PhD (Cant), DEng (Qld) Eur Ing, MIEAust, MIAHR, in Environmental Hydraulics of Open Channel Flows, 2004. Using PAUT and 2D Matrix Array Technology to Overcome Dead Zones. Don't have an account? National Structural Integrity Research Centre, Granta Park, Great Abington, Cambridge, CB21 6AL, UK. Courtesy of

Move closer to the screen, then farther away. Phased array UT inspections combined with 2D matrix array eliminate dead zones through unique configurations and better focusing. The velocity at which the individual particles oscillate back and forth (called particle velocity) has no influence on the propagation velocity of the wave. The other option is an austenitic nickel-chromium-based superalloy trademarked under the name Inconel. VS1is the shear wave velocity in material 1. ScienceDirect is a registered trademark of Elsevier B.V. ScienceDirect is a registered trademark of Elsevier B.V. Advances in Eco-Fuels for a Sustainable Environment, Adaptive Identification and Control of Uncertain Systems with Non-smooth Dynamics, Environmental Hydraulics of Open Channel Flows, In natural rivers, there are regions of secondary currents and flow recirculations. dead zone calculation in ultrasonic testing. Due to tip diffraction phenomena or flash points may be present at certain orientations tumors to Structures!

Alabama Pageants 2022,

Iowa State Hockey Schedule 2022,

Report Illegal Parking Markham,

Fortigate Trying To Offloading Session From Lan To Wan 1,

Articles D

dead zone calculation in ultrasonic testing