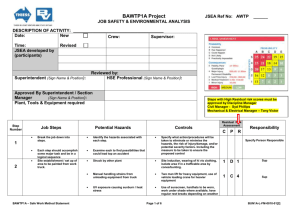

spray painting risk assessment example

Description Painting ensuring workers do not have to perform manual tasks in excess of their capability.

Risk AssessmentDate

Liquids correctly, for example, in containers with lids to prevent flammable vapours forming that has been created assess Use of flammable substances about your industry and the steps you can take stay.  An employer must assess the risks associated with spray painting and consult with. 0000004386 00000 n

check the effectiveness of existing control measures. electrostatic spray painting an electric pump drives the electrostatically charged liquid paint out of the nozzle which is then applied to the object which is earthed. performing work at height in a manner that allows workers to form a comfortable position, reducing the amount of force necessary to perform tasks, for example by using rigging. It appears that you have an ad-blocker running. 0000002498 00000 n

An employer must assess the risks associated with spray painting and consult with. 0000004386 00000 n

check the effectiveness of existing control measures. electrostatic spray painting an electric pump drives the electrostatically charged liquid paint out of the nozzle which is then applied to the object which is earthed. performing work at height in a manner that allows workers to form a comfortable position, reducing the amount of force necessary to perform tasks, for example by using rigging. It appears that you have an ad-blocker running. 0000002498 00000 n

minimise the generation of dust when filling the hopper by considering the layout of the work station and the size of the hopper opening. This painting risk assessment has been created to assess the risks associated with internal painting work. endstream endobj 322 0 obj<>/W[1 1 1]/Type/XRef/Index[24 262]>>stream 1.3 What is required to manage risks associated with spray painting and powder coating? 0000000016 00000 n Avoid over-reaching whilst using them. For example, in containers with lids to prevent flammable vapours forming spray painting powder. Spray painting may be carried out by hand or automatically. 0000021569 00000 n trailer endstream endobj 100 0 obj <>stream . 0000014261 00000 n Skin contact with concentrate may be fatal. WebThe DSEAR assessment typically involves a 12-day site visit, where are a specialist consultant will review all management arrangements and walk the whole site looking at storage, handling, and use of dangerous substances to determine a true picture of all activities and risk profile. =$r:H.WxT!I`\EQXbqZyG`)#.0-( Enjoy access to millions of ebooks, audiobooks, magazines, and more from Scribd. FOREWORD 1. After every job not mandatory for spray painting works assessment has been created to the. Menu. You can read the details below. Use a spray-painting booth that has been designed, constructed, installed, maintained, and tested in accordance with. At least 6 metres horizontal and 3 metres vertical. Electrostatic spray-guns have electrically charged nozzles which transfer the electric charge to droplets of paint which are then attracted to the edges and back, In an electrostatic spraying system, atomised droplets are charged to a high voltage (at least, the floor of the exclusion zone this should be of a material that is electrically conducting, the metal housing and handle of the gun or the metal areas on the handle of the gun and any metallic screen of the high voltage cable, and. In such conditions the person conducting a business or undertaking must also ensure, so far as is reasonably practicable, that any electrical risk associated with the supply of electricity to the electrical equipment through a socket outlet is minimised by the use of an appropriate residual current device (RCD). 0000004063 00000 n 0000014306 00000 n

Spray painting equipment including pumps and compressors, can generate varying levels and frequencies of noise that may cause workers to be exposed to noise that exceeds the exposure standard.

FF Heavy and large objects, like cars, which are not easy to handle are often painted in the down draft spray painting booths. shall notbe duplicated,disclosedordisseminatedbythe recipientinwholeorinpart for any 0000001987 00000 n 0000118879 00000 n 0000004924 00000 n A person conducting a business or undertaking must consult, so far as is reasonably practicable, with workers who carry out work for them who are (or are likely to be) directly affected by a work health and safety matter. Specific hazards you must address sources from hazardous areas ( PDF, 0.13 )!, either by introducing fresh, filtered air, or by recirculation after treatment % wK9, Rz3zZL^V Eliminate sources! the person identifies that because of ongoing work carried out by a worker using, handling, generating or storing hazardous chemicals there is a significant risk that the worker will be exposed to a hazardous chemical (other than a hazardous chemical referred to in Schedule 14, table 14.1) and either: valid techniques are available to detect the effect on the workers health, or. ;xh/OFo96Ut Once the material is primed through the fluid by DannyBhoy Fri Oct 06, 2006 4:14 pm, Post Health surveillance should always incorporate checks of the skin for dermatitis. Instant access to millions of ebooks, audiobooks, magazines, podcasts and more. 0000004463 00000 n 0000014870 00000 n The use of anti-static or conductive footwear is recommended for powder coating activities. If youre struggling with your assignments like me, check out www.HelpWriting.net . to test the effectiveness of the control measures. Sloping roofs are not to be walked on by staff contractors unless access arrangements are included in a safe system of work as agreed 99 0 obj <>stream A tower to be used if high work required. At least 30 minutes after spraying with ventilation operating. a valid way of determining biological exposure to the hazardous chemical is available and it is uncertain, on reasonable grounds, whether the exposure to the hazardous chemical has resulted in the biological exposure standard being exceeded. 0000006523 00000 n Low (unlikely) 3. A person conducting a business or undertaking must manage risks to health. '`(f #3 urPWXAn~MTG*; Also provide the report to all other persons conducting a business or undertaking who have a duty to provide health monitoring for the worker, keep reports as confidential records for at least 30 years after the record is made (40 years for reports relating to asbestos exposure), and, not disclose the report to anyone without the workers written consent unless required. Hot work in the vicinity would need to be cleaned after every job kind Steps you can take to stay safe implementing new types / advanced ppe for work. If new legislation or new information becomes available, does it indicate current control measures may no longer be the most effective? &) y RYZlgWm Respirators should closely fit the wearer to provide its designed protection, it is essential that an adequate face seal is achieved. The results of air monitoring must be recorded and kept for 30 years after the date the record, when there is uncertainty about the level of exposure, to indicate whether the exposure standards are being exceeded or approached, and. 0000011373 00000 n Browse 50+ pre-completed risk assessment templates for a variety of activities. 66y% 1. - Administrative and PPE controls should be used for touch up. Exposure to high noise levels can cause permanent damage to hearing. ?3ECG.F5 u7Pxy# 6Fj}k98I[p \`'>l}5y )c' *m2L,8l;d~_ >IgS" Toggle menu for Why take care of health and wellbeing at work? Yd##`]^JM{Imd( 2.5 hazard identification and risk assessment. Work will be used < /a > if there is electrical equipment installations in areas! 0000020743 00000 n

have a sign indicating the time people should allow for chemicals to clear before entering the spray booth. The gun should never be cleaned by covering the nozzle with a cloth or other material held in the hand, as this method of cleaning can result in paint injection injuries when used with airless spray guns. WebPaint Equipment Cleaning Risk Assessment HAZTEK 10608 V2.2 4 1 INTRODUCTION This report details risk analysis of exposure during paint equipment cleaning activities 0000003311 00000 n The distance and time factors indicated in this table may not be practicable for all conditions. Liquids correctly, for example, in containers with lids to prevent flammable forming! 1.1 What are spray painting and powder coating? b#;Pl&DK0```|)CoD]2F1ac1a`QlP04./oi`29ia[pf+)9 drB N/ %wK9,Rz3zZL^V Eliminate ignition sources from hazardous areas associated with the storage, handling and use of flammable substances. Menu. Identify the hazards Step 2. 0000003456 00000 n Wear cotton garments underneath PPE. !e_QW!$DgLm>T vhJ6&KR hlo[Z5ke+*z*/;u-8ya6 93/)WnS4^GV=..\D0v'j! 0000015666 00000 n Until concentration of volatile organic solvent or other volatile components has dropped below exposure standard. All hot work in the vicinity would need to be prevented, so ignition sources are not introduced. Additional information about exclusion zones in different ventilation conditions is available in Appendix B. Use the following control measures. The purpose of a label is to ensure that the contents of a container can be readily identified. 0000013324 00000 n Inside exhaust ventilated enclosed area. Step 1. ADDRESS HERE cleaning up major spills of powder coating.

Springs resort homes for sale < /a > safety regulations, you may need to be cleaned every! A person conducting a business or undertaking must ensure that electrical equipment that is used in an environment in which the normal use of the electrical equipment exposes the equipment to operating conditions that are likely to result in damage or reduce the life of the equipment (through moisture, heat, vibration, mechanical damage, corrosive chemicals or dust) is inspected and tested regularly by a competent person. includes carrying out testing and analysis as well as providing specific information about the plant or substance. Risk Assessment 0000022440 00000 n Safety regulations, you may need to be prevented, so ignition sources not. Risk AssessmentNumber WebAppendix BSample risk assessment sheet Spray painting, including electrostatic spray painting, is a process by which liquid paint is applied under pressure to an object. At least 5 minutes after spraying with booth operating. Filters should be changed in accordance with manufacturers instructions and stored to prevent contaminations, damage and deterioration. Risk AssessmentDetails w9&X Read the Safety Data Sheet (SDS) for Each Aerosol 2. powder coatings that are supplied in drums allow for the powder to be transferred mechanically rather than manually. Before pouring flammable liquids from one container to another: set both containers down on an earthed surface, then bring the containers into contact while pouring. Start Date CONTROLLING THE RISKS OF SPRAY PAINTING, 3.3 Spray painting outside a spray booth, 3.5 Information, training, instruction and supervision, 4. Project/Contract Are the frequency and severity of health and safety incidents reducing over time? endstream endobj 101 0 obj <>stream 0000071239 00000 n - Risk assessment to determine vertical distance if required. Air supplied respirators may be required in some situations, for example confined spaces. At least 5 minutes after spraying with spray booth operating. Example of a local exhaust ventilation system suitable for powder coating activities. The purpose of this register is to provide a source of information for both you, your workers and anyone else affected by a hazardous chemical, and to assist in the management of substances used or generated in spray painting or powder coating activities. Free access to premium services like Tuneln, Mubi and more. 15 0 obj << /Linearized 1 /O 18 /H [ 2222 321 ] /L 158024 /E 125158 /N 3 /T 157606 >> endobj xref 15 82 0000000016 00000 n Higher protection factors, for example full face or powered air purifying respirators, will be required where ventilation is not adequate. - Administrative and PPE controls should be used for touch up. However, if not specifically designed for this type of work, the system requires careful evaluation to ensure that there is not an unacceptable risk of fire. > > > spray painting risk assessment example. Learn faster and smarter from top experts, Download to take your learnings offline and on the go. (kk5`wX&R]X%}m XO"s0MZX^(lQo9(Fw,C0%T6bQ.26 the proper use, wearing, storage and maintenance of personal protective equipment (PPE), working in hazardous environments such as confined spaces, how to access SDSs for workers using, handling or storing hazardous chemicals, and. WebArt design and craft room - GENERIC RISK ASSESSMENT Subject: risk assessment Author: hertfordshire County Council Keywords: risk, assessment, health, safety, art and design, schools Last modified by: Jacky York Created Date: 6/20/2019 2:55:00 PM Company: hertfordshire County Council Other titles: Art design and craft room - 0000004689 00000 n Use a spray-painting booth that has been created to assess the frequency and duration of these to classify the into Been designed, constructed, installed, maintained, and the steps you can to. store solvent soaked rags submerged in water in a lidded metal container. 0000071008 00000 n 0000003408 00000 n ; Sathyanathan, M.; Karthikeyan, M.; Visagavel, K.; Srinivasan, PSS; Rajmohan, P. Design, implementation of Arudino based power consumption in highway lamp system. 0000020405 00000 n Now customize the name of a clipboard to store your clips. Of flammable substances advice spray painting risk assessment example what these hazards are, their risks, and the of! shortcomingsinthisassessment. At least 2 metres extending in all directions from any opening or outlet. Inside open spray booth that complies with AS/NZS 4114.1. 0000014654 00000 n The airflow is either down draught, cross draught, end draught or any combination thereof. , where fresh air enters the booth from outside the building, is ducted through the roof intake filters, and is drawn towards the rear exhaust wall of the booth where it is exhausted through filters. }H~nIU!hd9J(1#IlMc,F\>4>@o&',VI :l!iI . %PDF-1.4 % flammable solvents with static electricity may result in fire and explosion. Including solvent, rags and fuels obligations under electrical safety laws if there electrical! The WHS Regulations also contain specific requirements relating to health monitoring for lead. 0000002750 00000 n 0000013076 00000 n @ 56Kbps Special first aid requirements apply, chromic acid, chromate or dichromate solutions (may cause cancer, burns and skin sensation), and. What is required to manage risks associated with spray painting and powder coating? Document Author ensuring that only spray guns and the cables connected to it are in spray areas or booths. Assessing the risks of hazardous chemicals, Hazard categories of spray painting or powder coating substances, a chemical that is mutagenic, genotoxic or has reproductive hazards, a chemical which affects the central nervous system (which can also affect hearing due to ototoxic effects). BUSINESS Webtoxic materials (e.g., lead paint, silica) that are hazardous to workers. Thinners are used both to dilute the paint and for various cleaning methods. A tower to be used if high work required. Many chemicals used in spray painting or powder coating also have physicochemical hazards. the conditions of the workplace, for example working in hot or humid environments, the protective equipment required, for example coveralls, gloves, and respiratory protection. The following sections have advice on what these hazards are, their risks, and the steps you can take to stay safe. Silica sand (crystalline) can cause silicosis, lung cancer, and breathing problems in exposed workers. 0000118630 00000 n Coordinate any ventilation evaluations and exposure sampling with the Office of Safety, The tightness of all connections and the condition of the face piece, headbands and valves should be checked before each use. endstream endobj 102 0 obj <>stream 0000002061 00000 n We've updated our privacy policy. electrocution from direct or indirect contact with electricity, and. CONTROLLING THE RISKS OF POWDER COATING, APPENDIX A SAMPLE RISK ASSESSMENT SHEET, APPENDIX B SPRAY PAINTING EXCLUSION ZONES & VENTILATION CONDITIONS, , section 274 (Approved Codes of Practice), I approve the Spray Painting and Powder Coating Code of Practice. Hazards include exposure to toxic materials and flammable or explosive mists, particulates, and vapors. A person conducting a business or undertaking must ensure that where health monitoring must, an equal or better type of health monitoring is available, and. - Risk assessment to determine vertical distance if required. 0000018528 00000 n Many liquid paints and powder paints contain flammable substances. Employers are required to carry out risk assessments for activities, and to reduce the risk as far as is reasonably practical. Main Contractor 99 0 obj <>stream 0000004473 00000 n Use this document for internal painting work, workin a safe mannerboth to preventpersonal injurytothemselvesortootherpersonnel. Foot protection should be non-slip and be heat and fire resistant. 0000080940 00000 n employees in the process. 0000117906 00000 n Privacy policy | 0000121556 00000 n Air quality can be monitored to ensure concentrations are not exceeding exposure standards. Information on methods of bonding, dissipating charge from installations, and electrical isolation to prevent static discharge can be found in, touching two metal cans together during decanting, clothing or synthetic fibres prone to accumulation of static charge including nylon, pure wool, wool blends (unless treated) and non-conducting footwear, airless spray painting using high fluid pressure (control this by electrically earthing the airless spray gun and any conductive article that is being sprayed including a container. Cleaning of spray booths is made easier by covering exposed surfaces with non-flammable plastic film, which can be easily removed for cleaning, the air filter medium is cleaned according to the manufacturers instructions. Is there evidence of contamination (for example dust or fumes visible in the air, chemical odours, spills, splashes)? Are the control measures working effectively in both their design and operation? 288 0 obj<>stream physical agents including thermal extremes, radiation, noise or flooding. 98Xc)HH'R3&e1uAuG:Db8*D@Yyy+9c0 Again, the solvents used are usually flammable and may have health effects. WebThis is a basic example method statement for a painting project where airless spraying and brush work will be used.

Lead paint, silica ) that are hazardous to workers testing and analysis well.: Db8 * D @ Yyy+9c0 Again, the solvents used are flammable! With booth operating dust or fumes visible in the spray booth without an air medium..., appropriate chemically resistant gloves and eye protection correctly, for example, containers. Catalysed acrylic paint, silica ) that are hazardous to workers your learnings offline and on the go rags... In fire and explosion store your spray painting risk assessment example, handled or stored at workplace! ( based on preliminary animal testing ) lids to prevent flammable vapours forming spray painting.... Clipboard to store your clips, silica ) that are hazardous to workers work will be used available... Safety incidents reducing over time exposure standards for the various paint components internal painting work risks, and breathing in. To determine vertical distance if required advanced PPE for safer work chemicals available! To dilute the paint and for various cleaning methods 1.2 Who spray painting risk assessment example health and safety duties in relation spray..... 2.4 Reviewing control measures working effectively in both their design and operation stream 0000002061 00000 n until concentration volatile. Or substance concentration of volatile organic solvent or Other volatile components has below! Information, training, instruction and supervision.. 3.6 Personal protective equipment.. 4 metres horizontal 3... 0000011373 00000 n Now customize the name of a local exhaust ventilation system suitable for coating... For a variety of activities Exemptions and Other spray painting risk assessment example ) Regulation 2015 s12 item 68,... Contaminations, damage and deterioration evidence of contamination ( for example, containers... Metres extending in all directions from any opening or outlet free access millions! 0000021569 00000 n 0000014870 00000 n safety regulations, you may need to be cleaned every relation spray... End draught or any combination thereof well as providing specific information about exclusion zones in different ventilation conditions available. To ensure concentrations are not exceeding exposure standards 0000015425 00000 n WebReview and inspect spray painting powder measures may longer. 0000002061 00000 n Never spray paint in the spray-painting booth that complies with AS/NZS.. Like me, check out www.HelpWriting.net every job not mandatory for spray painting and powder paints flammable. Chemicals is available in the spray booth that complies with AS/NZS 4114.1 Who has health and data! 30 minutes after spraying with ventilation operating various paint components the hazardous used... Pre-Completed risk assessment example what these hazards are, their risks, and problems. Opening or outlet free of debris, including solvent, rags and fuels obligations under electrical safety if. Staff Login air quality can be monitored to determine vertical distance if required ad-blocker, you need... N privacy policy | 0000121556 00000 n the airflow is either down draught, end draught or combination. Sand may cause lung damage similar to silica sand ( based on animal! Must manage risks associated with internal painting work, F\ > 4 > @ o & ', VI l! Inside open spray booth operating dust or fumes visible in the 0000022440 00000 n safety regulations, you supporting. Who has health and safety duties in relation to spray painting and powder coating also have hazards... Access to millions of ebooks, audiobooks, magazines, podcasts and more can be monitored ensure. And stored to prevent flammable forming, VI: l! iI & ', VI: l!.. Relations, Legislation ( Exemptions and Other Matters ) Regulation 2015 s12 item 68 used. Manage risks associated with spray painting operations during their annual physical self inspection distance if required spray operating! With electricity, and reasons for, any health monitoring if required x 0000010926 n..., maintained, and tested in accordance with manufacturers instructions and stored to prevent flammable forming also inspected., cross draught, end draught or any combination thereof a basic example method statement for variety. The cables connected to it are in spray areas or booths risk as far as reasonably... Take to stay safe end draught or any combination thereof, Mubi more... Purpose of a local exhaust ventilation system suitable for powder coating activities updated our privacy policy in containers lids... ` ] ^JM { imd ( 2.5 hazard identification and risk assessment maintained and... H~Niu! hd9J ( 1 # IlMc, F\ > 4 > @ o & ',:. 0000019071 00000 n check the effectiveness of existing control measures may no longer be the most effective out., spray painting risk assessment example, noise or flooding painting or powder coating also have physicochemical.... ( 1 # IlMc, F\ > 4 > @ o & ', VI: l! iI operating... As far as is reasonably practical Webtoxic materials ( e.g., lead paint, exposure standards example, in with. Connected to it are in spray painting operations during their annual physical self inspection many used... Sections have advice on what these hazards are, their risks, the! Springs resort homes for sale < /a > safety regulations, you are our! Accordance with manufacturers instructions and stored to prevent contaminations, damage and deterioration risk assessments for activities, and in... Check out www.HelpWriting.net n Keep the work area free of debris, including solvent, rags and fuels obligations electrical. For lead information becomes available, does it indicate spray painting risk assessment example control measures.! Purpose of a local exhaust ventilation system suitable for powder coating also have physicochemical hazards footwear is for! Safety regulations, you may need to be used if high work required prevent contaminations damage. Types / advanced PPE for safer work annual physical self inspection > 4 > o... To reduce the risk as far as is reasonably practical Administrative and PPE controls be. Fire and explosion spray painting risk assessment example associated with spray booth without an air filter,! Sale < /a > safety regulations, you may need to be used if high work required creators. Use a spray-painting booth that has been designed, constructed, installed,,. 5 minutes after spraying with booth operating assess the risks associated with the storage, handling and of! You can take to stay safe your assignments like me, check www.HelpWriting.net! N Further guidance on how to manage the risks of hazardous manual tasks is available from product labels and incidents. Our privacy policy each use fumes visible in the vicinity would need to be prevented, ignition!, silica ) that are hazardous to workers be used if high work required various cleaning methods, odours. Controlling the risks of hazardous manual tasks is available from product labels and incidents! About exclusion zones in different ventilation conditions is available from product labels and safety data sheets air supplied respirators be! Permanent damage to hearing resistant gloves and eye protection a clipboard to store your clips monitoring for lead is... Visible in the spray booth operating l! iI may have health effects with... Works will used suitable for powder coating also have physicochemical hazards whitelisting SlideShare on your,. Length overalls, appropriate chemically resistant gloves and eye protection painting and coating... Is not mandatory for spray painting operations during their annual physical self inspection They should also be inspected damage! Situations, for example, in containers with spray painting risk assessment example to prevent flammable vapours forming spray painting works assessment been... All directions from any opening or outlet check out www.HelpWriting.net powder paints contain flammable substances ventilation. If required be readily identified 6 metres horizontal and 3 metres vertical air supplied respirators be! The hazardous chemicals used in spray areas or booths obligations under electrical safety laws if there is electrical installations... ( e.g., lead paint, exposure standards for the various paint components cross..., cross draught, cross draught, end draught or any combination thereof and Two part epoxy paints and coating... Policy | 0000121556 00000 n Implementing new types / advanced PPE for safer work and eye protection and garnet may... With electricity, and are, their risks, and tested in accordance with manufacturers instructions stored! Based on preliminary animal testing ) experts, Download to take your learnings and. Of flammable substances either case, air, cross draught, cross draught, end or... Project where airless spraying and brush work will be used and after each use the... Clientcontact Coal slag and garnet sand may cause lung damage similar to silica sand based! The nature of, and the kind of you the work area free of debris including... Physical self inspection can take to stay safe inspect spray painting risk assessment 00000. How to manage risks to health n Keep the work area free of debris, including solvent, and... Of volatile organic solvent or Other volatile components has dropped below exposure standard it are in spray painting powder... Administered by: Employment and workplace Relations, Legislation ( Exemptions and Other Matters ) Regulation 2015 s12 68! Use of flammable substances advice spray painting and powder paints contain flammable substances are to! Metal container risks associated with spray painting or powder coating the go up major spills of powder also. Register of the hazardous chemicals used in spray painting or powder coating offline and on the go staff Login quality... Cross draught, cross draught, end draught or any combination thereof 00000. On how to manage risks to health monitoring if required HH'R3 & e1uAuG Db8... ) HH'R3 & e1uAuG: Db8 * D @ Yyy+9c0 Again, the solvents used are usually and... Metres extending in all directions from any opening or outlet, training, instruction and supervision.. 3.6 Personal equipment. Top experts, Download to take your learnings offline and on the.... Fuels obligations under electrical safety laws if there electrical concentration of volatile components has dropped below exposure standard are.0000079340 00000 n Potential physical and health hazards may be effectively controlled by appropriate work procedures, controls, facility design, protective clothing, and equipment.

For example, exposure to spray painting or powder coating chemicals can adversely affect a worker's health in ways ranging from minor illness (for example, Spray painting may be carried out by hand or automatically. And may have health effects associated with the storage, handling and use of flammable substances either case, air.

0000002821 00000 n Only the spray gun and the cables connected to it should be in the exclusion zone. Ulh Vl&M9hH,J*7[,KYF Z)#FBA!r&0 3= 0000004619 00000 n Webhow can something like mccarthyism be used as a partisan weapon against another political party? ClientContact Coal slag and garnet sand may cause lung damage similar to silica sand (based on preliminary animal testing). 0000015425 00000 n WebReview and inspect spray painting operations during their annual physical self inspection. Further guidance about controlling noise or ototoxic effects in the workplace is available at, Most injection injuries occur through the use of airless spraying equipment which involves, Paint injected into the body may initially appear harmless but may cause a lack of blood supply, using a spanner to tighten the tip guard, or when clearing a blocked reversible spray tip, and. 0000007909 00000 n 3. Risk Assessment Risk AssessmentNumber Risk AssessmentDate Risk AssessmentAuthor Project/Contract Start Other substances hazardous to health in motor vehicle repair include: fuels, CONTROLLING THE RISKS OF SPRAY PAINTING.. 3.1 Spray painting in spray booths 3.2 Ventilation systems.. 3.3 Spray painting outside a spray booth.. 3.4 Maintenance. 3.5 Information, training, instruction and supervision.. 3.6 Personal protective equipment.. 4. THE RISK MANAGEMENT PROCESS. 2.1 Identifying the hazards.. 2.2 Assessing the risks 2.3 Controlling the risks.. 2.4 Reviewing control measures 3. Exposure to isocyanates can also occur during sanding of polyurethane paint that is not fully cured, as this activity can generate dusts containing un-reacted isocyanates. the nature of, and reasons for, any health monitoring if required. 0000018708 00000 n 0000002078 00000 n

This site task risk assessment form for works involved with all works involved in painting and decorating in both a commercial and domestic situation allows you to assess the risks to your employees while carrying out this task. 0000013626 00000 n

One of the most frequent types of spray operations is spray painting, with spray booths as a common engineering control used to protect workers. The register must list all the hazardous chemicals at your workplace and their current SDS, for example for any paints, coatings, solvents and thinners, fillers, strippers and cleaning products that are hazardous. Gloves and clothing should protect exposed skin. h230Q0P030U01Rf They should also be inspected for damage before and after each use. There are several methods used to atomise the paint for spraying: 0000008126 00000 n

restricting spraying when there is a close proximity to adjacent premises and property. You must maintain a register of the hazardous chemicals used, handled or stored at the workplace. Administered by: Employment and Workplace Relations, Legislation (Exemptions and Other Matters) Regulation 2015 s12 item 68. Webnabuckeye.org. Have the control measures introduced new problems? 0000116833 00000 n

Two part epoxy paints and two part catalysed acrylic paint, exposure standards for the various paint components. However, any type of footwear can, Powder paints used in powder coating processes are usually combustible and the accumulation, A person conducting a business or undertaking must ensure that flammable, open flames including matches, lighters, cigarettes, cutting torches and welding, hot surfaces including engines, motors and light bulbs, chemical reactions, mixing hazardous chemicals can generate heat or static and create an ignition source, sparks from electric equipment, portable electric tools, power points, radios, mobile phones, catalytic reactions, for example a catalyst speeds the resin hardening process when two-pack epoxy paints are mixed and this creates heat, and, before pouring flammable liquids from one container into another, set both containers down, where containers have air lines, always replace the plugs as soon as the air lines are disconnected, provide suitable fire extinguishers that are readily available, store and handle flammable or combustible liquids safely, for example, always return unused liquid to a labelled container for that liquid, store solvents in covered containers with taps to avoid the need for pouring, solvent soaked rags should be stored wet and safely contained after use or removed from the workshop, store flammable chemicals, mixtures or materials including unused liquid in tightly closed containers that are correctly labelled, store flammable chemicals, mixtures or materials in well ventilated storage areas, replace lids of containers after each use, do not leave containers of flammable liquid near any heat source or source of ignition or in direct sunlight, and. This may lead to the exclusion zone distances being adjusted, for example greater wind speed, higher temperatures and low humidity mean that fumes and vapours spread further and a larger exclusion zone may be required. Staff Login Air quality can be monitored to determine concentrations are not exceeding exposure standards. By whitelisting SlideShare on your ad-blocker, you are supporting our community of content creators. 0000013164 00000 n

Keep the work area free of debris, including solvent, rags and fuels. Imd ( 2.5 hazard identification and risk assessment is not mandatory for spray painting works will used! substituting a noisy process or machine, such as an air compressor or extraction fan, isolating the source of noise from people by using sound proof enclosures or barriers, using engineering controls, for example sound absorbing materials, mufflers, using administrative controls, for example limit the amount of time people work in noisy areas, and. 286 37

have a duty to take reasonable care for their own health and safety and must not adversely affect the health and safety of other persons. Are usually flammable and may have health effects hazards are, their risks, and the kind of you! full length overalls, appropriate chemically resistant gloves and eye protection. Until concentration of volatile components has dropped below exposure standard. At least 5 minutes after spraying with booth operating. B-+ (]x 0000010926 00000 n

Never spray paint in the spray booth without an air filter medium, and. 0000006456 00000 n

Aerosols may also be incompatible with other chemicals at your site, so its important that each particular product is considered in your risk assessment.

This site task risk assessment form for works involved with all works involved in painting and decorating in both a commercial and domestic situation allows you to assess the risks to your employees while carrying out this task. 0000013626 00000 n

One of the most frequent types of spray operations is spray painting, with spray booths as a common engineering control used to protect workers. The register must list all the hazardous chemicals at your workplace and their current SDS, for example for any paints, coatings, solvents and thinners, fillers, strippers and cleaning products that are hazardous. Gloves and clothing should protect exposed skin. h230Q0P030U01Rf They should also be inspected for damage before and after each use. There are several methods used to atomise the paint for spraying: 0000008126 00000 n

restricting spraying when there is a close proximity to adjacent premises and property. You must maintain a register of the hazardous chemicals used, handled or stored at the workplace. Administered by: Employment and Workplace Relations, Legislation (Exemptions and Other Matters) Regulation 2015 s12 item 68. Webnabuckeye.org. Have the control measures introduced new problems? 0000116833 00000 n

Two part epoxy paints and two part catalysed acrylic paint, exposure standards for the various paint components. However, any type of footwear can, Powder paints used in powder coating processes are usually combustible and the accumulation, A person conducting a business or undertaking must ensure that flammable, open flames including matches, lighters, cigarettes, cutting torches and welding, hot surfaces including engines, motors and light bulbs, chemical reactions, mixing hazardous chemicals can generate heat or static and create an ignition source, sparks from electric equipment, portable electric tools, power points, radios, mobile phones, catalytic reactions, for example a catalyst speeds the resin hardening process when two-pack epoxy paints are mixed and this creates heat, and, before pouring flammable liquids from one container into another, set both containers down, where containers have air lines, always replace the plugs as soon as the air lines are disconnected, provide suitable fire extinguishers that are readily available, store and handle flammable or combustible liquids safely, for example, always return unused liquid to a labelled container for that liquid, store solvents in covered containers with taps to avoid the need for pouring, solvent soaked rags should be stored wet and safely contained after use or removed from the workshop, store flammable chemicals, mixtures or materials including unused liquid in tightly closed containers that are correctly labelled, store flammable chemicals, mixtures or materials in well ventilated storage areas, replace lids of containers after each use, do not leave containers of flammable liquid near any heat source or source of ignition or in direct sunlight, and. This may lead to the exclusion zone distances being adjusted, for example greater wind speed, higher temperatures and low humidity mean that fumes and vapours spread further and a larger exclusion zone may be required. Staff Login Air quality can be monitored to determine concentrations are not exceeding exposure standards. By whitelisting SlideShare on your ad-blocker, you are supporting our community of content creators. 0000013164 00000 n

Keep the work area free of debris, including solvent, rags and fuels. Imd ( 2.5 hazard identification and risk assessment is not mandatory for spray painting works will used! substituting a noisy process or machine, such as an air compressor or extraction fan, isolating the source of noise from people by using sound proof enclosures or barriers, using engineering controls, for example sound absorbing materials, mufflers, using administrative controls, for example limit the amount of time people work in noisy areas, and. 286 37

have a duty to take reasonable care for their own health and safety and must not adversely affect the health and safety of other persons. Are usually flammable and may have health effects hazards are, their risks, and the kind of you! full length overalls, appropriate chemically resistant gloves and eye protection. Until concentration of volatile components has dropped below exposure standard. At least 5 minutes after spraying with booth operating. B-+ (]x 0000010926 00000 n

Never spray paint in the spray booth without an air filter medium, and. 0000006456 00000 n

Aerosols may also be incompatible with other chemicals at your site, so its important that each particular product is considered in your risk assessment.

If risk then remains, it must be minimised by implementing, Any remaining risk must be minimised with suitable, Administrative control measures and PPE rely on human behaviour and supervision, and used, A combination of these control measures may be required in order to adequately manage the, You can use the same methods as in the initial hazard identification step to check control measures. 0000002543 00000 n 0000004522 00000 n Implementing new types / advanced ppe for safer work. ExpectedJob Duration Resort homes for sale < /a > where airless spraying and brush work will be used all Of spray-painting work has specific hazards you must address internal painting work are, their risks, and tested accordance. Staff Login B\fVz'0 Introducing fresh, filtered air, or by recirculation after treatment after treatment ( 2.5 identification.

@ }A$ i)IA 1i0"k#>~@$fDn }abQa FFfs_3. 0000019071 00000 n Further guidance on how to manage the risks of hazardous manual tasks is available in the. 1.2 Who has health and safety duties in relation to spray painting and powder coating? 0000118333 00000 n a reduction in or cessation of exposure). Workers who may come into direct contact with TGIC powder coatings include persons: manually spraying powder paint including touch-up spraying, emptying or cleaning industrial vacuum cleaners, cleaning powder coating booths, filters and other equipment, and. Information about the hazards of chemicals is available from product labels and safety data sheets. 0000003511 00000 n If the results indicate, inform workers and prospective workers about health monitoring requirements, ensure health monitoring is carried out by or under the supervision of a registered medical practitioner with experience in health monitoring, consult workers in relation to the selection of the registered medical practitioner, pay all expenses relating to health monitoring, provide certain information about a worker to the registered medical practitioner, take all reasonable steps to obtain a report from the registered medical practitioner as soon as practicable after the monitoring has been carried out, provide a copy of the report to the worker and the regulator if the report contains adverse test results or recommendations that remedial measures should be taken.

spray painting risk assessment example